London Guitar Repairs

Guitar Setups and Repairs London

Guitar Repairs London. Let us restore musicality to your guitar, whether you’re a hobbyist or a working musician, whether you’re in need of a repair, adjustment or custom work. We will stand behind every repair we do, 100%. London Guitar Repairs is the place for repairs, setups and modifications to your guitar & stringed instruments including re-strings, setups, re-frets, refinishing, neck resets, vintage restoration, relic-ing, blasting, cracked tops, broken or loose acoustic guitar braces, pickup installation, custom electronics, bone nuts and saddles, binding and major reconstruction. Perfect work, done FAST, at low cost. We are open Monday -Saturday 8am-9pm. London Guitar Repairs is a full service repair shop ranging from setups and truss rod adjustments to complicated neck resets and refrets.

Guitar Repairs London – Acoustic and Electric Instruments

Guitar Setup London – While-You Wait & Next-Day Repairs

Electric Guitar Making and Repair Convenient London Location

Guitar Repairs and Setups London. Expert technicians keep your instruments and equipment in peak playing condition with expert repairs, upgrades and maintenance.

Guitar repair has been a large part of London Guitar Academy from the start. Terry Relph Knight, an expert luthier with over 30 years experience, and his experienced repair staff are well known for their set ups, custom wiring, fret jobs, wood work, custom guitar building, and much more. With excellent diagnostic skills, high quality guitar repairs, and vintage restorations. We are also the top recommended company for repairs and re-frets on session great Hugh Burns guitars.

RESTRING

- 6 string guitar – £60 plus strings

- 12 string guitar – £70 plus strings

Guitar Repair | Amp Repairs London

London Guitar Repair runs our own high quality guitar repair shop in London. Guitars need regular servicing to maintain playability, electronics, action and tuning intonation. Changes in weather such as temperature, central heating and humidity as well as wear and tear on frets, nuts, saddles and strings can affect stringed instruments greatly.

Repairs, Maintenance and Modifications | Guitar London

Guitar repairs London, Amp repairs, Guitar Setups, re-fretting, Headstock repairs and full re-wires, spares and custom parts

To find out more about my guitar repair and maintenance services or to book a free consultation simply call 07957230354 or email Santi @ info@londonguitaracademy.com

REPAIRS AND MAINTENANCE LONDON

Guitar Repairs, Advice, Maintenance & Guitar Setups London. Low prices, fast service, and 100’s of loyal customers. Guitar Repairs London for YOU!

- Your one-stop-shop for all things musical including quality guitar repair and music lessons!

- All aspects of the guitar’s adjustment are covered including, Fret board conditioning, Truss rod adjustment, Acoustic pick up installation. Acoustic neck angle adjustment

- Repairs for Fender, Gibson, Martin, Taylor, Guild, Gretsch, and many more.

- Fretboard cleaning and conditioning, electronics cleaning, truss, intonation, string height, and pickup height adjustments. A full pro go over head to body

- Pickup services are offered from complete rewinds to waxing/potting.

- Guitar Repair, modification, Servicing, Fretting,Pickup winding; Waxing/potting & Customising

- Set-up. Fret Leveling & Dressing, Wiring Issues and Neck/Bridge/Nut/Tremelo Adjustments

- The turnaround is the fastest in London the rates are super fair and most importantly the work is done right with the player in mind

- From simple input jack fixes to pickup replacements to customers creative wiring mods and full rewires

- All custom work can be completed and executed to the highest professional standards

ALWAYS PROVIDING OUTSTANDING CUSTOMER SERVICE.MOTIVATED BY THE DESIRE TO SATISFY THE NEEDS OF EACH UNIQUE PLAYER.MODERN AND VINTAGE GUITARS SERVICED WITH SUPERIOR CRAFTSMANSHIP SPECIALISING IN THE REPAIR AND RESTORATION OF ALL ELECTRIC,ACOUSTIC GUITARS & AMPLIFIERS IN LONDON. We’ve gained an excellent reputation for our work!

[rule_top]

Below is an examples of the detailed repair logs we issue with our repairs.

Repair Log: 2006 Epiphone Custom Shop Limited Edition Casino vintage sunburst SN:xxxxxx made by the Un Sung Musical Instrument Co., Ltd., Inchon, Korea.

Copyright retained by Terry Relph-Knight 17/09/17

Current value – purchased second hand for £450. Can be found on offer for as high as £799. Current production has a Casino VS (no Bigsby) which sells at a street price of £438.10.

Following the upgrade work perhaps £600

Delivered with a black, Epiphone branded, hard case.

A 2006 Epiphone Custom Shop, Limited Edition, Casino thin-line, electric guitar. Two piece (scarfed headstock) mahogany D profile narrow neck, 41mm at the nut. Truss rod (4mm hex hey) adjusts at the nut, 3 screw access under an E branded cover plate. Hollow body of maple ply with basswood bracing. Cream binding top and bottom edge of the body and on the neck. 12 inch radius rosewood fretboard with off-white plastic dots and 22 medium jumbo frets. Body is finished in a black/brown to dark transparent yellow, vintage sunburst. The neck and headstock are painted black with the Epiphone brand inlaid in mother of pearl at the top of the headstock. The headstock is of the narrow style with in-curved sides and a pronounced ‘open book’ crest. The internal paper label shows the model as “Casino VS” (vintage sunburst). A round silver ink stamp on the back of the headstock just above the line of the nut, states the guitar is Limited Edition Custom Shop. The Epiphone Custom Shop brand is used on limited run models.

The specifications for the current Casino on the Epiphone web site give a neck width of 1.68 inches. The neck on this one measures 1.635 and the nut itself is just a little narrower than the neck.

Hardware – Epiphone Kluson style 18:1 tuners (stamped with the Epiphone epsilon brand) with integral nickel plate oval metal buttons. Epiphone licensed Bigsby B700 model trapeze vibrato tailpiece. Two Epiphone P90 pickups with chrome plated dog-ear covers (the base plates of the P90s have their two end tabs soldered to the inside of the dog ears on the covers), Epiphone ABR-1 style Tone-O-Matic bridge (nickel plated). The two bridge posts, which have a small slot in the top for height adjustment with a flat screwdriver, are M4 metric thread and they screw in to 12mm diameter metal inserts in the top of the guitar that seem to be set into the bracing. Unfortunately the guitar is missing the floating pickguard with the Epiphone E metal logo and these pickguards are hard to find and expensive to replace. Metal insert witch hat knobs (reflector knobs).

Problems – Brought in for reduction of the very high action (previous owner used it for rhythm playing) and a general check over.

Has a loose output jack, pickup switch and bridge tone control. The treble side bridge post is screwed much further into the guitars top than the post on the bass side. The bridge is set very high and is highest on the treble side. Guitar is generally a little dirty and the finish looks very dull. Judging by traces of an abrasive white power found under the Bigsby and by the state of the finish, the previous owner tried rubbing down the gloss of the finish, possibly to make it look like an older guitar.

With the strings removed the neck had a tiny amount of forward bow. The truss rod was loose with no tension applied. I tightened the truss rod until the neck was flat and then applied a fret rocker test.

The test shows the following frets are high; 10 just a little on the high E side, 12 particularly on the low E side, 14, 18 and 20 a little in the middle.

Work done – Fitted a Goldo Tune-o-Matic bridge with roller saddles with added M3 bridge locking grub screws. Dropped the bridge height from the high setting as received to adjust the action and adjusted the depth of the two threaded bridge posts that are screwed in to inserts in the top of the guitar.

Tightened up the nuts on all the controls, on the switch and on the output jack. Dabbed on some clear nail varnish to help lock the nuts in place.

Partial fret level – filed down the high frets with a crowning file and smoothed and buffed with Crimson fret rubbers.

Cleaned and polished the guitar, trying to buff out the fine scratches left by the previous owner.

Re-built the licensed Bigsby. Removed the old tension roller. Manufactured two plastic conversion sleeves to support the Callaham 3/16 tension roller axle in the 3/8 inch holes in the axle mounts. Drilled and tapped the back of the Bigsby frame for 3mm grub screws to lock the conversion sleeves and axle in place. Removed the inner circlip from the string roller to stop it binding against the bearing housing. Inserted two fibre washers to take up the slack between the bearing in the Bigsby arm and the inner face of the arm bracket. The string roller and the arm now swing with very low friction. Re-mounted the Bigby on the guitar and clipped a Vibromate String Spoiler to the string roller to make re-stringing easier.

Filed the nut slots to accommodate the heavy bottom / light top string set, to reduced string sticking and to reduce clearance over the first fret to improve intonation and ease of play.

The Bigsby – The ‘licensed’ Bigsby vibrato is a B700, trapeze tailpiece model. The main change that Epiphone have made to the design, presumably in order to save money, is that rather than drill the 3/16” holes in the aluminium frame for the front roller axle and drill and tap for a grub screw in the frame leg, Epiphone chose to cast larger 3/8” inch holes (roughly 3/8” the holes actually taper from the outside in). A 1/4” roller axle is used, running in push-in nylon bushings inserted, both into the frame and into the ends of the thin tension roller tube. The axle is retained by circlips at either end rather than the grub screw through the frame as on a geniune Bigsby.

I wanted to upgrade the Epiphone licensed Bigsby by fitting a Callaham solid, stainless steel tension roller (3/16” shaft 0.187 inch, roller is 2.215 long by ?? diam) and a drilled through string shaft (0.374 inch diam, Epiphone is 0.388, Bigsby is 0.373). These parts are designed to fit a genuine Bigsby and neither are a direct retro fit in the Epiphone licensed version of the Bigsby. The tension roller can perhaps be made to fit with suitable 3/8 to 3/16 reduction bushings. The string shaft is narrower (0.374 inches diameter compared to 0.388 inches of the existing Epiphone shaft) and would probably be too loose a fit. The options on the string shaft are, either remove all the string pins and the string roller from the frame, drill through the string roller and countersink the holes to allow the strings to be threaded through the roller. Or – to try fitting a Vibromate String Spoiler for easier string loading. I eventually settled for the Vibromate which seems to work OK without shifting and altering the tuning.

Unlike my Korean made, but genuine, Bigsby B5, on the Epiphone licensed version there are retaining circlips fitted on either end of the string shaft, holding it in place in the frame. My B5 has only one circlip on the outer end and its lateral movement is limited at the other end by the arm bracket that is attached to the string shaft with a grub screw running into a mating hole in the shaft. On the Epiphone the two circlips are too close to the roller bearings and they mechanically interfere with the bearing housings. As a result, when the Epiphone string shaft is rotated it feels like the bearings are full of sand. I removed the circlip on the arm bracket end and limited the side-to-side slack by fitting some washers on the shaft between the vibrato frame and the arm bracket.

After removing the Epiphone tension roller, I reamed out the tapered holes in the vibrato frame with a 9.5mm drill. I manufactured two new plastic bushings from ABS 0.75 inch long 3/8” diameter spacers with centre hole drilled out to 5mm. These were cut down to 14mm long and a compression slot cut through one side.

Repair log – Tokai SS60 model Silver Star Stratocaster copy, SN: XXXXXXX, made in Japan between 1976 and 1982

© Terry Relph-Knight 09/01/18

Current value – £ 500

Current weight = 3.6kg or 7.94lbs.

While still making excellent guitars today, Japanese maker Tokai became known in the 1970’s for their affordable copies of the iconic American electric guitars. This guitar was based on early copy of the Fender CBS era Stratocaster. The client had purchased this guitar quite recently with the intention of having it completely re-built, with many parts to be replaced with new modern equivalents.

While these Tokai guitars are certainly very good copies, they are copies of US originals that were arguably at their lowest ebb in terms of quality. While the Tokai wooden parts and pickups are usually very good, some of the general hardware is of low quality. In particular the synchronised vibrato bridge, which on many Tokai S type guitars is a chrome plated, single piece, zinc alloy casting, with cast zinc alloy saddles. Some Fender guitars of the period also feature solid cast zinc bridges as a cost saving (the more complicated and expensive machined steel inertia block, bolted to a hardened steel bridge plate, with folded steel saddles was judged unnecessary by Fender management at the time) so exactly who was copying who isn’t clear.

Discussed Modifications

Replace all the electronics with new CTS pots, Orange Drop tone cap, Oak switch etc.

New knobs

Replace all screws with new – black screws on the pickguard

New black conical strap studs

Electrically screen the guitar with copper tape

Replace the bridge with a Wilkinson steel block bridge with vintage saddles

Fit a new brass nut

New Grover locking tuners

Replace the old bent metal string trees with Graph Tech trees

New Switchcraft output socket

New D’Addario waterfall swirl scratch plate

New silver mirror tremolo cavity cover

Fit a set of 10 to 46 strings

Set-up and adjust the intonation

Body – The body is 3 piece, probably of Sen Ash, finished in metallic silver. Body has 3 routes for single coil pickups. The control route is stamped with 12=1SG Y.

3 bolt, micro tilt, chrome plated steel neck plate, 2.5mm hex key to adjust the micro-tilt. The neck pocket was shimmed with two pieces of paper so whoever did it, either did not understand the micro-tilt system, or couldn’t find a suitable hex key. There is no internal shielding. All the internal routing is extremely clean and tidy.

Neck – Maple, one piece, 3 bolt neck with black plastic dots finished in a high gloss poly that has darkened to a ‘vintage’ amber. The fret surface is 7.25 inch radius with 21 thin ‘vintage’ frets, a soft V profile, narrow 41mm nut width to 55mm at the last fret. Standard Fender necks are 43mm at the nut to 55mm at the last fret. The nut itself measures 39mm and may not be original. Quite heavy fret wear under the plain strings down to the eighth fret. Large Fender CBS style headstock.

Truss rod adjusts from the headstock with a 4mm hex key bullet nut with a 5mm thread. 12 = 2 is stamped on the end of the heal. Two bent metal string trees with a spacer.

The Tokai logo in black with a gold outline, SILVER STAR in black and the serial number in black are printed on the front face of the headstock.

Hardware – The pick guard is a black three ply guard with 11 fixing screws. Strange little 5 way pickup switch.

The bridge is an extremely poor, single piece Zinc casting, that combines the top plate and the inertia block. The entire thing is chrome plated (these single piece die cast bridges seem to be fitted to all the old Tokai Strats). It is fitted with block cast zinc alloy saddles.

The bridge fixing screws and strings are on a 55mm spacing. The screw in vibrato arm is stainless steel with a white tip and obviously not the original.

Pots – Japanese, Vol 308.2K, tone 314.5K, tone 307.3K, all 20% law. 0.047uF plastic film tone cap.

Problems – In for a general re-build, cleaning and set-up.

Work done – Guitar disassembled, cleaned and polished. Body cavities lined with copper screening tape. New D’Andrea pick guard fitted with CTS pots – 250K 10% curve for volume and 250K 20% curve tone for a smoother control of tone, wired for first tone neck pickup, second tone bridge pickup. Tone cap – 0.022uf Orange Drop. Oak 5 way pickup selector switch fitted, with a black switch tip secured with a drop of superglue. Cheap Japanese output jack replaced with a Switchcraft, fitted with a screened cable. One piece Zinc alloy bridge replaced with a Wilkinson WV6SBCR (chrome plated steel bridge plate with a steel inertia block) which has the narrower 2 1/8 inch string spacing and the oval mounting holes that will allow for the odd Tokai bridge mounting screw spacing. The narrower string spacing reduces the likelihood of the strings falling off the edge of the fretboard. Tremolo springs replaced with the new Wilkinson, as the old Tokai springs had hooks that were too long for the Wilkinson block. Tokai spring claw retained as it matches the spacing of the original tremolo tension screws. Truss rod nut removed, lubricated and replaced. Original Tokai conical springs used for the pickup mounting the Tokai pickups rather than surgical tubing.

Fitted a thin plastic shim to the long edge of the neck pocket to reduce neck slop.

Brass nut fitted in place of the original too small and loose plastic nut. I used a standard 43mm wide nut with a 35mm string spacing and filed the ends down to match the narrow 40mm wide neck. This means the guitar now has the standard Fender string spacing at the nut, along with the narrow string spacing at the bridge. This places the strings across the the fretboard in a very comfortable position – wider at the nut for ease of fingering, but at the same time further from the fretboard edge on the higher frets.

Guitar re-assembled, set of RotoSound Yellows (10 to 46) fitted (twists soldered on the three plain strings) set-up and intonated. Tremolo cavity fitted with a silver mirror cover plate.

Painted on some clear nail varnish across a crack in the finish that runs from the lower corner of the neck pocket in an attempt to stabilise the finish and minimise the possibility of a large chip coming away.

Pickup measurements

Tokai

L (H) R (K) Q

Neck 2.206 6.205 0.2746 @ 120Hz

2.2116.4922.143@ 1000Hz

Middle 2.216 6.207 0.2755 @ 120Hz

2.2136.5162.137@ 1000Hz

Bridge 2.193 6.228 0.2718 @ 120Hz

2.196 6.510 2.122 @ 1000Hz

0.186 inch diameter, I assume Alnico 5, unbevelled magnets, set flat on the bottom with a smooth 7.25inch radius stagger on top. Grey forbon top and bottom plates. The coil windings are sealed under black fabric tape and the coil lead outs are thin plastic insulated wire so I cannot make any comment on the coil wire type. Pickup wires are black and blue plastic insulated solid copper wire. The pickups are all the same polarity with the South pole uppermost, (no Reverse Wound Reverse Polarity – RWRP – here). These pickups are wax dipped. Pickup covers are black plastic. The covers don’t fit flush, they are short of the forbon baseplate by about 1mm which allows clearance for the two lead out wires.

All three pickups are manufactured to identical specifications. They are wound a little hotter than the Tokai pickups on the clients sunburst Tokai and would seem a close match to the early 50’s classic Fender Strat pickups.

Pickup heights recommended by Fender

With the strings depressed at the last fret. Measure clearance from the bottom of the string to the top of the pickup pole piece.

Bass Side Treble Side

Vintage style 6/64″ (2.4 mm) 5/64″ (2 mm)

Tools required for adjustment

5mm Hex Key for the truss rod

1.5mm Hex Key for the bridge saddle heights and for the arm tension

Pozidrive No.1 for the intonation screws

Parts –

£ 6.50 set of strings

£ 5.00 for copper tape

£ 4.50 for teflon insulated silver plated wire and tie wraps

£ 31.50 Wilkinson WV6SBCR vibrato bridge

£ 3.92 Set of 3 black Strat knobs with white legends

£ 5.25 One 250K 10% law CTS pot

£ 10.50 Two 250K 20% law CTS pots

£ 2.10 1 x Orange Drop 0.022uF capacitor for tone control

£ 5.42 Oak five way selector switch

£ 3.60 Switchcraft jack socket

£ 95.00 Set of Grover locking tuners

£ 2.00 Silver mirror finish tremolo cavity cover

£ 30.00 D’Andrea blue swirl pearl pick guard

£ 9.00 Brass replacement nut

£ 2.60 2 x conical black strap buttons

£ 2.47 19 x pickguard screws @ 13p each

£ 0.72 6 x M3 by 35mm black hex button screws for the pickups @ 12p each

Parts total – £ 220.08

Tokai Springy Sound model numbers – which are usually engraved on the last fret or on the neck heel – generally break down as follows:

- ST-42 (1977 – 1979) – U-shaped neck, chrome hardware, non-Kluson type tuners, ceramic pickups, 3- or 4-piece sen ash body with poly finish

- ST-45 (1980 – 1981) – U-shaped neck, chrome hardware, non-Kluson type tuners, ceramic pickups, 3- or 4-piece alder body with poly finish

- ST-50 (1977 – 1984) – U-shaped neck, nickel hardware, Kluson-type tuners, alnico “E,” “U,” “V” or “VI” pickups, 3-piece alder or sen ash body with poly finish

- ST-60 (1977 – 1984) – V shaped neck, nickel hardware, Kluson-type tuners, alnico “E,” “U,” “V” or “VI” pickups, 2-piece sen ash or alder body with poly finish

- ST-70 (1982 – 1983) – U-shaped neck, nickel hardware, Kluson-type tuners, DiMarzio VS-1 alnico pickups, 2-piece sen ash or alder body with poly finish

- ST-80 (1979 – 1983) – V-shaped neck, nickel or gold hardware, Kluson-type tuners, DiMarzio VS-1 alnico pickups, 2-piece sen ash or alder body with nitro finish

- ST-100 (1979 – 1983) – V-shaped neck, gold hardware, Kluson-type tuners, DiMarzio VS1 alnico pickups, 1- or 2-piece sen ash body with nitro finish

- ST-120 (1982) – V-shaped neck, gold hardware, Kluson-type tuners, DiMarzio VS-1 alnico pickups, 1-piece ash body with nitro finish

All of the above models were available with a rosewood fingerboard, but this feature is very rare on ST-80 and higher models. Tokais can also be identified through their serial numbers, but there are some instances of departures from this system.

Repair log – 1963 Watkins Copicat MkII – tape loop echo/reverb unit SN: xxxx, made in London SW9, by Watkins Electric Music also known as WEM.

Repair Date – 09/09/16 Customer – xxxx xxxx

Terry Relph-Knight copyright retained

Price – The original price in 1962 was £38.10 (around £763 inflation adjusted). Today – £400 to £565, depending on condition. This one is graded as – ‘in good condition’

Description – A mechanical ¼ inch tape loop, valve, reverb / echo unit. This unit is a MkII valve unit, although the makers plate shows it as a ‘D.T.S.’ model (apparently D.T.S. means ‘death to Selmer’. Charlie Watkins was annoyed with Selmer because they had simply copied his earlier two head echo and this D.T.S. three head unit was his response).

Controls – Motor only on / off toggle switch, incandescent 6.5V indicator lamp, Swell control with anticlockwise on/off mains switch for the entire unit, Reverb control, Gain 1 control (input 1), Gain 2 control (input 2). Two ¼ inch mono jack sockets for input 1 and 2. Three push button keys for ‘Halo’, ‘Echo’ and ‘Repet’ (short for repetition? Rather than a misspelling of repeat).

Hardware – Case is made from 6mm plywood covered in two tone oatmeal and turquoise flecked rexine, with ‘gold’ piping and fittings. The tape transport is of 18 gauge steel plate, painted turquoise and silk screened in white with the logos and control labels. Mounted on the left of the plate is a two roller, cast aluminium tension arm, incorporating a permanent magnet for erase. From left to right there is a record head followed by three playback heads. After the heads there is a fixed aluminium tape guide followed by the motor spindle / tape capstan. The electronics are mounted on a separate bent steel plate under the transport plate. A captive 2 core mains lead (replaced with a grounded 3 core) and two captive screened cables for a footswitch and the signal out, exit the left edge of the transport plate and are stored in a recess in the left end of the case.

Valves – This unit has a Mullard ECC83, a Brimar 6BR8 and a Mullard ECC83 – These may be the original valves. Each half of one ECC83 is used as an input amp for the two input channels (inputs are 1Meg each), the 6BR8 (a dual tetrode plus triode) is used for the record head driver and for the bias oscillator and the second ECC83 is used as the playback amplifier. All the signal mixing is by a passive resistor network, high impedance output.

Problems – Produces a horrible noise (hum) when the Echo push button (middle button of three) is depressed. No power indicator light. Bottom grille is smashed. Badly needs a new tape loop. Mirror insert missing from the middle of one of the knobs. Two core mains lead and the output cable has an ugly terminal block splice in it.

Work Done – Unit disassembled and cleaned (the inside of the case under the transport had some rather alien looking dust bunnies in it). Heads cleaned with isopropyl alcohol. Middle playback head, bottom grille, indicator lamp and output cable replaced. Two core oval mains cable replaced with a three core Live, Neutral and Earth cable, so the unit complies with current safety regulations. Two mismatched securing screws replaced with matching screws. Tension arm bearings lubricated. Replacement Marriott head measures 1038 ohms, 589mH. Bad head is open circuit, shows more wear and a wider head gap.

Diagnostic notes – The circuit diagram of these Watkins units shows that the three playback heads, which are spaced along the tape path at increasing distances from the record head, are all wired in a series chain into the input of the playback amplifier. Three push button switches (labelled ‘Halo’, ‘Echo’ and Repet’ – yes it really is labelled Repet) are wired, in the up position, to short across each head winding. Pushing each switch down removes the short and includes each playback head in the playback circuit chain. If any of the play heads are open circuit the playback amplifier sees an open circuit when that head is selected by its push button, and the output produces a loud hum.

Parts replaced – Playback head, Bottom grille, lamp, 3 core mains cable, output cable, 2 fixing screws, knob insert. Note – Parts are extremely hard to find. There is now only one source.

Repair Log: 1968/71? Fender Coronado II in Antigua finish, hollow body, left handed SN:XXXXXX, according to the serial number look-up on http://www.guitardaterproject.org – made at the Fullerton Plant (Fender – CBS Era), USA in 1971. The neck date indicates 1968.

Copyright reserved by Terry Relph-Knight

Value – maybe £2,000, the guitar is not in mint condition, but it is left handed

Weight – 3.3Kg or 7.27lbs

In 2013 Fender released a Coronado re-issue (no trem) at around £592 street, now discontinued. Although some of these guitars are still in the retail chain. These are ‘modern player’ guitars. They keep the original aesthetic, but add ‘upgrades’ or changes to make the guitars more player friendly. The re-issue ‘modern player’ Coronado has a solid centre block, a pinned Gibson style Adjust-O-Matic bridge and two Fender Fidelitron humbucking pickups. The re-issues only have a trapeze tailpiece, no tremolo. This original guitar is likely of most interest to collectors since the design does not work well as a players guitar.

The Coronado is a Roger Rossmeisl design from the CBS years, produced from 1966 up to 1972. A German immigrant to the USA in 1953, Rossmeisl had trained as a luthiere in Mittenwald, Germany. He worked at Gibson and then Rickenbacker, where he had Mosrite founder Semie Mosely as an apprentice, before moving to Fender.

The Coronado was inspired by the Beatles use of the Epiphone Casino thin-line hollow guitar and the following fashion for Epiphone style thin-line hollow and semi-hollow guitars. Sales of Stratocasters had fallen away and Fender wanted a hollow body guitar to compete. It is a bolt neck, in this case left handed, thin-line hollow guitar (there is a block under the tremolo) with a bound body, two bound F holes and a floating pickguard. The II indicates this is a two pickup version, there was also a single pickup version, a twelve string and two basses.

The Coronado II’s were made with a number of variations and colours, such as a transparent pick guard (with black script) instead of the black burst white with the script ‘Antigua’ guard on this one, a two screws and a bar string retainer instead of a string tree, two smaller knobs for the tone controls and the addition of the lettering ‘Coronado II’ in black to the headstock.

Some Coronados had a black/white chequerboard pattern in the binding. The chrome pickup surrounds have a point on one side and although these were usually fitted with the point down towards the tailpiece, some Coronado’s have them the other way up. Sometimes you will see them with one pickup pointing up and one down! These may simply be guitars where the owners have decided to rotate the pickups. Just about every picture on the web shows the floating bridge in a different place and angle. Assuming the dimensions and pickup positions weren’t changing a lot out of the factory then the intonation on most of these guitars must be way off.

It seems to have been a ‘thing’ for the Coranado’s to have the name of the finish written on the pick guard. Coronado’s in the Wildwood, dyed beechwood version, have ‘Wildwood’ on the guard.

Delivered with a solid Gator case and with a nylon strap. Missing a tremolo bar. Apparently these bar’s are the same as those used on Fender Mustangs, but replacements are extremely hard to find.

Body – The double cutaway, arched, thinline body is of beechwood ply with a white/black/white binding front and back. It is finished in a black to off-white (the white appears yellow under the aged clear coat) burst with black sides, a paint scheme known as Antigua. Trivia fact – the Antigua burst was apparently invented because of a manufacturing error. The glue Fender used to fix the body binding on some of the Coronado bodies left a stain, or chemical burn, around the edge of the body. The thin black burst was applied to hide this ‘burn’.

Other paint schemes in the Coronado line feature more conventional sunbursts or solid colours. Coronado’s other than the Antigua had a black painted headstock and dot fret markers.

The finish on this guitar has a number of long cracks in it and the odd chip. Particularly under the bridge pucks and the trapeze tremolo pads where the paint has stuck to the rubber pads.

The neck pocket has three Fender, thin Forbon shims, two in red and one thicker shim in black.

The stamps for T OLLMER and D CRAWFORD are just visible in the neck pocket. Also a large hand scrawled T.

Neck – A one piece, 25.5 inch scale, 7.25 inch radius, flame maple neck (some birdseye) with a bound, light reddish-brown rosewood board and MOTO block inlays. There are multiple cracks across the width of the binding and some sweat has penetrated through these and discoloured the edge of the maple neck. 21 small frets, some visible fret wear down to the seventh fret across all strings. The nut (width 1 and 19/32 inches, or 41mm) stops inside the binding, since this is already a narrow neck this makes for a slightly narrower string spacing (33.5mm E to E, standard is 34mm). The headstock is burst painted to match the body and carries a script Fender logo in black with a gold outline. Despite what the serial number seems to indicate, the end of the neck is stamped with 19FEB68B.

In February of 1964 (until around 1973) Fender introduced a selection of custom neck sizes:

A: A narrow 1 1/2″ neck, B: The standard 1 5/8″ neck, C: 1 3/4″ neck, D 1 7/8″ neck.

All non-standard necks (ie A,C, D) could be ordered for an extra 5% above the retail price.

A & C necks are rare, and D necks are very rare, as virtually no one ordered one. The letter code does not refer to neck shape, only width.

So this neck is supposedly a B, a standard width 1 5/8 neck.

Hardware – One folded metal string tree on quite a tall plastic spacer on the E and B strings. Fender branded, Grover six-on-a-side customised Rotomatic tuners, with rounded rectangular pearloid buttons. These are fitted closely together (the spacing along with the large buttons make this guitar hard to tune) and five of these tuners have a small bevel on the locating screw lug that allows it to tuck in under the next tuner. The sixth tuner for the low E does not have a lug bevel, so the tuners must be fitted in the order of – 5 bevelled and the sixth without the bevel. The holes for these tuners seem to have been drilled a little over size by mistake because the Grover bevelled washers under the threaded collars have been supplemented with larger washers to cover the oversized holes drilled in the headstock. The tuners seem to require a stepped hole.

Two single coil, surface mount pickups with screw poles, fairly ornate chromed mounts (with a split to avoid circulating eddy currents, from what would be effectively a shorted turn, damping the pickup response), black tops. The chrome surrounds sit on artificial rubber/PVC gaskets, which of course, over time, tend to stick to the finish on the top of the guitar. Some Coronados where fitted with DeArmond pickups with Alnico rod magnets on spring loaded carriers, adjusted by six separate screws. The pickups on this guitar, which seem to be fitted to the majority of Coronado’s on the web, are probably also DeArmond, but are simpler in construction. It appears there are six rod magnet mounted in threaded cylinders which appear at the top of the pickup as six small slot head screw poles.

With the Mustang and the Coronado, Fender introduced the Fender Dynamic Vibrato, a two part system where the tremolo mechanism is separated from the bridge. The Coronado has a completely floating bridge that balances on two needle point bearing screws that sit in chrome plated, cast zinc pucks. The bridge has six adjustable barrel saddles. The two point pivot tremolo system has a heavy chrome string anchor bar and is loose trapeze mounted to a hook plate screwed to the guitars end block. The string tension is balanced by a double leaf spring, concealed in the tailpiece. The Coronado trem is similar to that used on the Jazzmaster, but differs in having a leaf spring and the heavy string anchor bar. The original Fender Mustang has the same heavy string anchor bar and the same tremolo arm, but uses two coil springs to provide counter tension to the strings.

The Mustang was and is an entry level, beginners guitar which sold in large numbers. Despite that even replacement Mustang tremolo bars (left handed) are hard to find.

Floating, Antigua burst scratchplate with ‘Antigua’ in black script.

Controls are Gibson style two volumes, two tones (all wired in reverse – see Diagnosis) and a three way pickup selector switch.

Problems – Entire guitar is very grubby, the bridge tone knob is loose and the intonation screw is missing from the bottom E saddle (a 4-40 5/8 apparently – available in packs of 12 from Strings Direct). On another saddle the intonation screw thread is damaged and the screw is jammed. Pickup switch seems stiff and unreliable. Top three tuners are loose on their locating screws and threaded collars. Oddly unbalanced output from the bridge pickup with the high E pole raised above the others. Missing the original left handed tremolo arm. Odd paint chips and surface marks where the guitar has knocked against white house-paint and this has transferred to the guitar surface.

Work done – Disassembled, thoroughly cleaned and polished the guitar. Polished and waxed the fretboard. Reconditioned the heads of the four neck ‘bolts’ and all other bolts and screws.

Tightened the output jack nut and painted on a little clear nail varnish to help lock it in place.

Disassembled the tremolo, cleaned, lubricated and reassembled.

Disassembled the bridge and cleaned all the parts with WD-40, re-assembled and replaced the missing intonation screw with the nearest US thread screw I had. Also cleared a crossed thread on one of the saddles. Removed the 3/32 inch hex wrench stuck to the back of the bridge pickup. This is the size of wrench used to adjust the bridge height grub screws.

Removed all six tuners, cleaned and replaced them on the headstock.

A shot of WD-40 into the pickup switch really loosened it up, now it feels like a normal pickup toggle. Similarly, isopropyl alcohol followed by a spot of light oil freed up all the controls. Electronics tested while the guitar was disassembled and it functioned with no faults, no crackles or dropouts (also later tested OK with the guitar plugged in), except for the discovery of the reversed control wiring.

Touched up some of the paint chips.

Guitar re-strung with a set of D’Addario EXL110 nickel wound 10’s and truss rod and bridge adjusted for best action. Bridge saddles adjusted for intonation correction.

Diagnosis – The neck tone pot had a ‘frozen’ shaft due to the shaft lubricant having thickened. As a result excessive turning force applied to the knob had caused the knob to loosen and spin on the shaft. All four controls show signs of the lubricant thickening.

For some bizarre reason all the controls are wired in reverse, so that maximum is anti-clockwise. Apparently the wiring harness used in the Fender Coronado line was manufactured by Rowe Industries of Toledo, Ohio and delivered as a completely pre-assembled set. Although there is no sign the wiring has been modified, the control reversal, if it is not original, could be the result of a re-wire.

Lifted the two pickups to clean under them and found a small hex wrench attached to the underside of the pickup poles by magnetic attraction. Obviously at some point someone had dropped the wrench inside the guitar and it ended up stuck to the pickup magnets.The top E pole screw had been noticeably raised to compensate for the higher volume from the other strings due to the increase in the upper magnetic field caused by the wrench.

The bridge, which has similarities to that used on the Fender Mustang, floats on two pointed pivot screws, one at either end, that sit in holes in two, completely floating, chromed pucks with rubber pads on their bases. Bridge height is adjusted through these two screws. The bridge should be oriented with the intonation screws towards the tailpiece. The saddles are hollow cylinders of nickel plated brass with string grooves, sitting in a trough in the bridge. These cylinders are graduated in three diameters – small, medium, large – to follow the fretboard radius – so small, medium, large, large, medium, small. They also have graduated string grooves, so each saddle is unique, one small saddle has a large groove for the bottom E and one a small groove for the top E. Small springs, with the intonation screws running through them, pass most of the way through the saddles. The screws and springs are all the same size. Unlike the Mustang / Jazzmaster bridges which are of folded steel, this bridge is cast from Zinc alloy and then chrome plated, as are the two pivot pucks.

Setting intonation on a completely floating bridge can be a bit of a problem since, not only do the saddle adjustments set the string length, but the entire bridge can be moved back and forth, or even slanted. For simplicity I have placed the bridge with the two pivot pucks up against the back edge of the bridge pickup as a stable reference point. Fortunately the wide bridge then allows enough travel in the saddles to achieve correct intonation on all the strings. The pivot bridge is held against its pivot points purely by string pressure and any tilt backwards or forwards of the bridge will affect intonation. The bridge should be adjusted to close to vertical on its pivots. The bridge height adjustment wrench can be used to make fine adjustments to the bridge tilt on its pivots by inserting it into one of the height grub screws and using it as a lever.

The chrome bar, trapeze mount, two point pivot tremolo, has a blued steel, string tension balance leaf spring, concealed in the hollow chrome plated, pressed steel tailpiece. This leaf spring is bolted to the bottom of the string anchor bar with two bolts on spacers that pass through two holes in the pressed steel tailpiece. A further two holes serve as ‘knife edge’ bearing points for the two tremolo pivots which are two short hex rods with a turned waist serving as a V pivot. These two rods screw in to the underside of the string anchor bar at either end. A small grub screw at the bottom of the tailpiece allows adjustment for the spring tension. The grub screw shifts a small roller up and down that is mounted on a further V shaped spring. The roller supports the end of the two layer, blued steel, leaf spring. Clockwise turns on the screw reduces tension on the leaf spring, the chromed bar string anchor tilts forwards and the notes flatten. Modern light gauge strings probably do not apply enough tension to apply the load this tremolo was designed for. It is likely that the tremolo was intended to be set by adjusting the screw so that the anchor pivot pillars sit at right angles to the tremolo shell. With 10s on the guitar maximum clockwise on the screw doesn’t quite achieve this.

Strings are loaded with the ball end towards the neck, run through and folded under the chrome bar tremolo string anchor, then up to run over the floating bridge.

As the trem arm is moved down, with the strings wrapped under the curved bottom of the string anchor, you might expect the strings to tighten and go sharp as the anchor rotates slightly anticlockwise. But in practice it is the movement of the anchor forwards (flat) and backwards (sharp) that dominates the tremolos action. In use the tremolo is quite gentle and, because of the long arm and the leaf spring, feels quite spongy, rather like a Bigsby.

Apparently a trem arm from a vintage Fender Mustang should fit the Coronado trem. Although the Mustang sold in much greater numbers than the Coronado Fender no longer supports spare parts for either of these guitars. Since the Coronado here is left handed that makes replacement arms even rarer. Allparts USA does carry a right-handed Mustang arm – BP-0274-005 Tremolo Arm for Vintage Mustang®.

The original arms apparently have a groove in them near the end of that leg and there is a 10-32 grub screw, threaded in to the end of the string anchor, that should be tightened to push on a pin encased in graphite loaded rubber that engages in the groove. This small rubber plug and pin from the original tremolo fell out and fell apart when I screwed the grub screw all the way in.

The G and D strings could do with a string tree because the tuner posts are quite tall and you have to be careful to wind the strings on so the turns pack neatly down the post to get any break angle across the nut. Either of these strings may exhibit nut buzz if the string comes off the post near the top, rather than winding smoothly down the post.

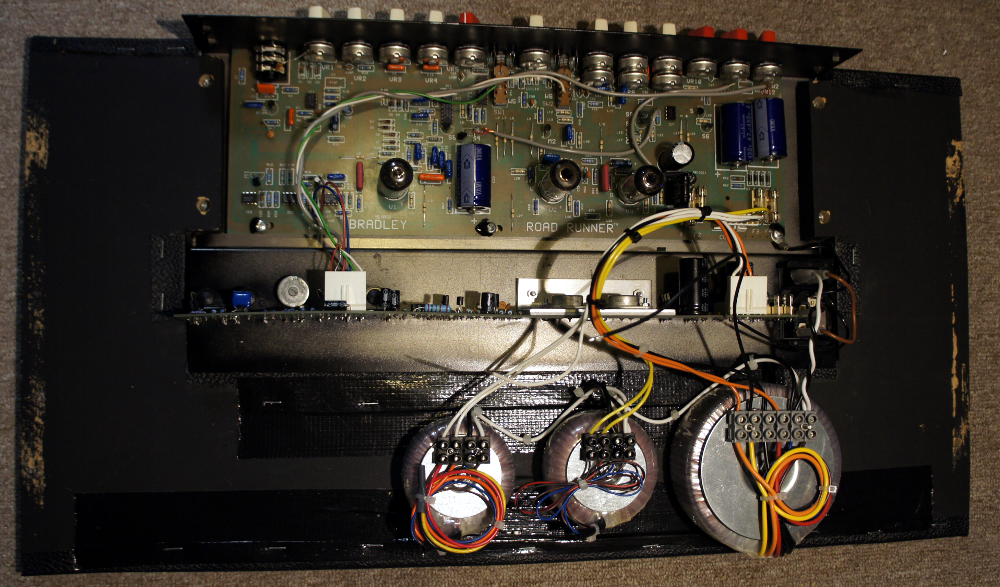

Repair log – 1980s? Bradley RoadRunner 100W 2 x 12 combo guitar amplifier SN: XXX

Date – 21/01/16. Copyright reserved, Terry Relph-Knight

Description – Bradley amplifiers are an early example of a hybrid valve / solid state design. Apparently they were made in Scotland and are extremely rare. They were made as 1 by 12 and 2 by 12 combos.

This example is a three channel, 2 by 12 combo amp with channel volumes and Master volume control. There are 3 dual triode valves (12AX7A) plus various op-amps in the pre-amp and the solid state 100W output stage uses a pair of complementary power MOSFETs (output transistors Exicon 10P20, 10N20 – £11.80 a pair on ebay). The plywood cabinet is covered in black tolex with chromed steel corner protectors. Size – 67cm long x 23.5 to 21.5cm tapered width x 38.5cm high.

3 Channels – Red channel with its own Drive, tone controls and Volume and a Blue channel with either Clean or Dirty with shared tone controls and Volumes for Clean and Dirty.

Cabinet fitted with two Eminence 12 inch SPK100 121505 8 ohm parallel wired to present a 4 ohm load to the amp.

Controls – Red channel drive, treble, middle, bass, volume, ch switch, Blue channel drive, Drive / Clean switch, treble, middle, bass, drive volume, clean volume, master volume. And an effects level return on the back panel.

Input jack on top panel. Effects loop send, series return, parallel return and foot switch on back panel. Also a jack for external loudspeaker.

Mains input through 3 pin IEC fused (T2A to T4A fuse) socket.

4 status LEDs –

A Red LED for the red channel a Blue LED for the blue channel, an Orange LED for blue drive and a Green LED for blue clean

Foot switch – The foot switch uses a stereo jack connection to switch from blue to the red channel when the ring is grounded, and from blue channel clean to drive when the tip is grounded. The foot switch is active when both push/push buttons are up (blue and green LEDs on).

With both buttons down the foot switch is defeated and the amp is switched to red channel and the blue channel, although not selected, is switched to drive (red and orange LEDs on).

Problems – Customer suspected problems with the loudspeakers. The loudspeakers were tested by connecting them to another amplifier – they are fine.

Amp shows no sign of life when plugged in and switched on. Front panel Drive / Clean push switch is jammed. Push on knobs onto round shaft pots don’t lock to the shafts, so control knobs tend to just spin round and round.

Mains fuse blown as well as several internal fuses.

It turns out the power transformer had developed an internal short.

Following the main repair work –

All the drive and volume controls including the Return level crackled when rotated and if the amp was switched to the Blue channel, with Drive selected, the Drive control turned up and the Drive Volume and Master Volume turned up, it went into internal feedback.

Work Done – The original custom mains transformer was replaced with three, off-the-shelf, toroidal transformers. Safety of internal mains wiring was improved. The mains input originally passed through two PC mount connectors and some PCB tracks. These connections were rewired directly to the power transformers. All blown fuses replaced. Entire amplifier cleaned. All 13 control knobs replaced with grub screw locked knobs. Rust around the hole in the front panel jamming the Drive / Clean push-push switch removed so the switch can move freely.

V2 replaced with a N.O.S Brimar ECC83 – the heaters of the old valve were open circuit. V1 replaced with a new Electro-Harmonix 12AX7 – the old valve was microphonic, the amp went into acoustic feedback oscillation when switched to the blue channel with the drive engaged.

Injected contact cleaner into all the pots to fix crackles.

The control panel Lexan decal was a little oversize and had chipped and split where it protruded. Improved its appearance by using a craft knife to trim away a straight strip of Lexan including the chips.

All of the electronics of the Bradley 100W Roadrunner is mounted onto the back panel with the original square frame power transformer bolted to the bottom of the cabinet. Here the three replacement toroidal transformers can be seen mounted along the bottom of the back panel. The MOSFET power amp stage and heatsink is visible in the middle of the panel. The controls and pre-amp PCB with the three valves are at the top of the panel.

Diagnostic notes –

Mains T2A slo-blo fuse is blown. Removed the amp chassis from the cabinet. This connects to the power transformer and the loudspeakers through 2 PCB mounted SIL Molex connectors through a short cable harness. The PCB mount pins on these are rather flexible and the PCB mount part moves around by a worrying amount.

Front panel Drive / Clean push-push switch was jammed because of rust around the hole for the push button in the front panel. Reaming out the hole slightly removed the rust and freed the switch so the button can move through its full travel.

F1 and F2 on the main PCB are blown. These feed 14V AC power to the bridge rectifier that feeds a 12 V DC regulator that powers the valve heaters with the two heaters in each dual triode wired in series. This supply is also used to feed the front panel LEDs. Also blown – F4 which appears to feed the rectifiers for the high voltage supply to the pre-amp valves and F80 which appears to feed the rectifier for the power to the transistor power amplifier.

To sum up, in addition to the mains fuse, one fuse in each pair for every supply rail in the amp – the supply for the valve heaters in the pre-amp, the high voltage supply for the valve sections of the pre-amp and the supply for the power amplifier, is blown.

Heaters are pins 4 (for the triode on pins 1,2,3) 5 (for the triode on pins 6,7,8) and 9 (center tap). Pins numbered clockwise looking up at the base of the valve. In this amp the heaters are run off a regulated 12V DC feed and the heaters centre tap on pin 9 is not connected.

Probably the next thing to do is to remove the power transformer from the cabinet, temporarily hook it up to mains and check the voltages coming out of it. Also hook up the loudspeakers (they already seem to respond correctly to a simple test with 3V DC from a continuity tester) to my 5W amp and run some audio through them.

Transformer disconnected and removed from the amp. When connected to mains power the secondary windings started smoking, so there is obviously a short in one of the secondaries. Continuity testing shows all the secondary windings are shorted together.

Testing across all the various power rails on the amplifier doesn’t show any shorts. With luck the only fault was in the transformer and the fuses protected all the electronics from permanent harm.

Old Transformer windings –

Wired for 240V AC in

32 – 0 – 32 V AC @ 2A (128VA so buy a 150VA) for the MOSFET power amplifier – orange – black – orange

14V AC @ 0.7A (9.8VA so 10VA) for the 12AX7 pre-amp valve series heaters (pins 4 & 5) pair of white wires

250V @ 75mA (18.75VA so 20VA) for the valve HT – pair of yellow wires

Connectors

CON81 (on power amp PCB) Numbered left to right on pin side

1 – Amp output

2 – Ground

3 – 32 V AC goes to F81 T2AL250V NOT blown

4 – 32 V AC goes to F80 T2AL250V blown

5 – Live 240V AC mains input !!!!! – Rewired exposed Live to go straight to the transformers.

6 – Neutral 240V AC main – Rewired exposed neutral to go straight to the transformers.

CON 1 (on pre-amp PCB)

1 – 14V AC to F2 T2AL250V blown – to 12V regulator for valve htrs and front panel LEDs

2 – 14V AC to F1 T2AL250V blown – to 12V regulator for valve htrs and front panel LEDs

3 – NC

4 – NC

5 – 250V AC goes to F4 T500mAL250V blown

6 – 250V AC goes to F3 T500mAL250V NOT blown

Measured voltages

1 to 2 = 14.76 V AC no valves plugged in. 14.2 V AC with all valves plugged in.

Valve heaters regulator = 11.8V DC no valves plugged in.

5 to 6 = 274V AC no valves plugged in

+344V across C23 no valves plugged in, 263V with V1, V2 no sign of heaters, 207V V3, 188V with 3 valves in

Replacement transformers

32 – 0 – 32 from http://www.airlinktransformers.com/ model CM0120233 120VA 230v to 2x33v £19 + VAT and shipping

Also a 12V and a 230V at £12 each

So £43 + 20% + post = £64.20

Fuses needed –

Mains – T2A L250V …. mains in

F1 – T2A L250V …. 14V AC – via a diode bridge rec. and DC regulator to valve heaters

F2 – T2A L250V …. 14V AC – via a diode bridge rec. and DC regulator to valve heaters

F3 – T500mA L250V …. 250V AC supply – rectified and smoothed for valve HT

F4 – T500mA L250V …. 250V AC supply – rectified and smoothed for valve HT

F80 – T2A L250V …. 32V AC for power amp – rectified to plus and minus 40V DC

F81 – T2A L250V …. 32V AC for power amp – rectified to plus and minus 40V DC

T = slow blow

L = Low breaking or glass fuse

So all these fuses are slow blow 20mm glass fuses rated at 250V. They are rated at either 500mA (Maplin 10pk GL56L £3.19) or 2A (Maplin 10pk GL62S £3.19).

Wire and fuses from Maplin (R.I.P.) – £12.39

A further 6 way connector CON80 on the power amp board connects the output of the pre-amp to the input of the power amp and feeds plus and minus, zener regulated supplies, for the pre-amp ICs (blue and red wires) derivedfrom the power amp 32-0-32 V supplies.

CON80

Pin 1 – signal – thin screened cable

Pin 2 – signal ground

Pin 3 – + 15V (?) Zener regulated, from power amp 40V through R105 100ohm – red wire

Pin 4 – -15V (?) Zener regulated, from power amp 40V through R106 100 ohm – blue wire

Pin 5 – Red ch / Blue ch switch – green wire

Pin 6 – Drive / Clean switch – white wire

Transformers

Airlink colour code – Sec1 start Orange finish Yellow, Sec 2 start Black finish Red

0160233

Brown Live 240V in White from power switch

Blue Neutral 240V in Black from IEC neutral

Black 33V Orange connector 81 pin 3 Power amp

Red & Orange C.T. Black connector 81 pin 2 ground

Yellow 33V Orange connector 81 pin 4 Power amp

0030206

Brown Live 240V in White from power switch

Blue Neutral 240V in Black from IEC neutral

Orange 12V White connector 1 pin 1 valve heaters

Yellow / Black C/T connected together

Red 12V White connector 1 pin 2 valve heaters

0030172

Brown Live 240V in White from power switch

Blue Neutral 240V in Black from IEC neutral

Black 230V Yellow connector 1 pin 5 valve HT

Red 230V Yellow connector 1 pin 6 valve HT

Repair Log: 1968 to 1972 Höfner violin bass model 500/1 SN: none visible

Copyright reserved T Relph-Knight 18/01/18

Value – £1,250 to 1,600

A new Höfner 500/1-64-0 can be purchased for £ 2,106.98

or the Höfner Vintage 500/1-62 Mersey for £ 1,842.50

The Hofner HCT-500 1-SB Contemporary Violin Bass Sunburst may be had for £499 inc VAT.

Known today as the ‘Beatle Bass’, originally designed by Walter Hofner in 1955 and launched at the Frankfurt Musikmesse in 1956, the Hofner 500/1 is a four string, short scale, electric bass guitar with a hollow violin style body.

The design suited the skills of the Hofner workforce, which had been making instruments of the violin family, and was intended to provide the bass player, who would previously have played an acoustic upright bass, with a very lightweight and compact electric alternative.

This version is fitted with two Hofner 512B single coil ‘blade’ pickups (Hofner Blade H512 £87.58 each, originally made from 1967 until 1970) with chrome plated metal covers mounted in black plastic rings, a wooden floating bridge and a nickel plated trapeze tailpiece. Originally fitted with a pearloid pick guard, the guard is missing from this bass (replacement H65/36 £27.33). The floating wooden bridge has a base and upper section mounted on two height adjustment thumb wheels, which as delivered, are screwed all the way down. The top of the bridge has four 5cm long sections of fret wire as saddles, mounted in four slots that run across the top of the bridge. The bridge is made of very dark rosewood. The narrow neck and 30 inch short scale makes this bass very comfortable to play even with a relatively high action. The light weight also helps with comfort. With the flat wound strings this instrument has a very fundamental rich, dark tone.

Neck – The one piece, glued in neck, of maple (or possibly sycamore) has 22 thin vintage frets and round pearloid markers on a rosewood fretboard. Nut width is 40mm. The neck is bound in white plastic with large oval black edge markers. The headstock has a thin black/white celluloid facing with the brand ‘Hofner’ in reflective gold script. A three screw cover allows access to the truss rod. ‘Genuine Hofner Original Made in Germany’ is stamped on the back of the headstock. The nut of laminated white / black / white celluloid only sets string spacing, as there is a jumbo zero fret.

The tuners are small and of an unusual ‘humped’ design made of nickel plated folded steel. The back of the tuner is a V shaped piece of spring steel that is rolled over at either end. The U shaped folded baseplate supports the worm gear shaft which passes through two holes in the upright folds. A further two holes on the other end of the baseplate support a steel pin. The sprung back is then hooked over the pin at one end and pushed down until it clips around the outside of the worm. The spring tension in this back clip pulls the worm tight up against the crown gear that is riveted to the end of the tuner post. Apart from a slight peening of the ends, there is nothing to hold these pins in place other than the tension of the spring. The pin on the D tuner had slipped out of its support hole at one end. The tuner pegs have fixed white plastic buttons.

With relatively small posts with small holes for the string ends, these tuners are designed to be used with custom made strings that transition into tapered ends that will fit the posts. The strings are described as 34 inch strings, which is the distance from the trapeze tail piece to ¾ of an inch past the nut, just below the tuners. LaBella make bass strings specifically for this instrument.

Body – The totally enclosed, but hollow body, has a book matched two piece spruce top plate, a one piece flamed maple back and flamed maple sides (may actually be European sycamore). The construction actually appears to be of laminated 4 ply with the maple backed by mahogany veneer. It is finished with a brown burst lacquer and bound top and bottom with white plastic with a black/white inner purfling. Two small white plastic strap buttons are screwed to the body, one to the heel and one to the end of the trapeze tailpiece.

Controls – The controls are mounted on a rectangular laminated MOTO celluloid plate fixed with four small screws over a hole in the lower bout. There’s a rotary volume for the neck pickup, three slide switches and rotary volume for the bridge pickup. The volume and tone have small round ivory plastic ‘teacup’ knobs with gold anodised central concave metal inserts (the Hofner Potiknob H909/15 replacements £9.43 each). The three slide switches switch between Solo / Rhythm, Bass (off) On and Treble (off) On. The Rhythm position drops the volume a little and the other two switches are for pickup selection (up is on). There is no control over tone. The electronics seem to function OK with no crackling (wrong – neither volume control actually provides any control over volume). The output jack is mounted on the side of the body.

String spacing at the nut is 32mm and the scale length is 30 inches (although the custom string length from the ball end to the start of the silk wound string taper is 34 inches).

Action at the twelfth fret is 3.5mm on open strings. Hofner specify 3mm E and 2mm G.

The aluminium height thumb wheels on the bridge were set as low as they will go so the only way to get a slightly lower action is to remove those wheels altogether. Either the bridge on the bass isn’t original, its feet had not been sanded to fit the curve of the top, or the intended factory action was always quite high. It really does not look as though this bridge has been properly fitted to this bass.

Delivered strung with flatwound strings 0.043, 0.061, 0.078, 0.100 as measured. The strings are old, worn and filthy. The low E string looks as though it was never suitable for this bass because there is no taper, the string at full diameter is fitted through the tuner (which has been drilled out).

Official Hofner strings

H1133B Beatle Bass Strings flat wound nickel 0.040, 0.055, 0.070, 0.100 £48.47+10 Thomman

The LaBella range of ‘Beatle’ bass string sets

760FHBB “Beatle” Bass Stainless Flats 50-100 (0.050, 0.065, 0.080, 0.100)

760FHB2 “Beatle” Bass Stainless Flats 39-96 £36 + 2 Bass Direct UK

760RHBB “Beatle” Bass Stainless Rounds 50-100

760NHBB “Beatle” Bass Black Nylon Tape 50-100 £25.17 + 6.26 post from USA

760THBB “Beatle” Bass White Nylon Tape 50-100

The light gauge stainless flats in 39 to 96, apparently are the strings used by Paul McCartney.

McCartney has also used Rotosound RS88LD Tru Bass flat wound black nylon strings 0.065, 0.075, 0.100, 0.115 £36.99 from Strings Direct.

You need Rotosound ‘Medium’ scale 35.25 inches from ball to silk. Rotosound print the scale on the string packets in small print.

Problems – In for cleaning (the bass is very grubby) and a set-up. D tuner was starting to fall apart. Volume controls do not work – on or off is about the best you can get. Bridge seems never to have been properly fitted, consequently the action is only just about low enough even with the height adjustment thumb wheels all the way down. The strings are completely dead and don’t appear to be a set that would correctly fit this bass.

Work done – Body and neck cleaned and polished. Fretboard buffed clean and polished. Strings cleaned. Re-positioned the tension pin on the D tuner and dabbed a little nail polish on either end to ‘glue’ it in place.

Intonation as delivered After re-stringing saddles moved

Low Error in cents

E +30 +10 +10 slot 4

A +25 -12 +3 slot 1

D +12 +5 0 slot 3

G +15 0 0 front slot 1

high

So with the old strings fitted, the intonation is generally very sharp – the bridge is too near the neck.

Bass returned on 15/02/18

Work to be done – The neck pickup has come loose and dropped into the body, control plate to be swapped for a new one supplied by the client, bridge to be properly fitted to the body/ Re-string with new LaBella 760FHB2 “Beatle” Bass Stainless Flats 39-96. Set up and intonate.

Fret 22 is loose on the treble side and needs glueing down. Case is falling apart. Some work done on restoring it.

Replacement controls

The replacement control panel is for a more ‘modern’ version of the bass, the circuitry is simpler (it has two 14mm diameter 500K controls – 443K and 485K 10% log curve – three 2 way slide switches and a 0.047uF tone cap, no other components).

The old panel has an 8.2K resistor, a 0.033uF cap, 250K pots and the top of the pearloid plate is engraved with the legends – Volume 2, Rhythm/Solo, Bass on, Treble on and Volume 1.

Unfortunately the new panel has no engraving and the three switches are attached with countersunk screws running through the panel. The old panel has the switches riveted to a brass sub-panel that is held in place by the pot nuts, which means that the new components cannot easily be transferred to the old panel to preserve the old look and the engraving.

Hofner seem to have used quite a variety of circuit configurations over the years and the new panel is not wired the same as the old one. The switches on the new panel simply switch either the bass/neck pickup or the treble/ bridge pickup on (or both on) with no extra tone or level shaping components switched in or out. The Rhythm/Solo switch either connects the selected pickup/s directly to the output or via the 0.047uF for a more treble tone.

Parts – LaBella 760FHB2 strings – £36 + 2 post

Returned on 16/04/18

The neck pickup had dropped out again. The screws, springs and threaded holes in the pickup all seem in good order. The only problem is that the two 25mm height adjustment screws only have 2mm extending past the threads in the pickup legs so if the pickup loosens at all the screws don’t have far to go before they come loose and the pickup falls out. Even so there should be enough thread and the pressure from the springs should stop the screws from loosening.

I added a couple of lock nuts to the protruding ends of the screws and as a further precaution painted these nuts with clear nail polish to glue them in place.